This is part one of a two-part series. Read Part Two Here.

Tom Evans, president and owner of Tom Evans Environmental Inc., an equipment supplier in the water and wastewater pumping and treatment fields operating in the Florida area, says that like much of South Florida, the Pompano Beach area has two distinct faces. “Pompano on the beach is probably as expensive as anywhere else in the Fort Lauderdale region because it’s all Atlantic oceanfront property. At some point, as you’re working your way west, you’re driving over a bridge, over the Intracoastal Waterway, and finding yourself on the mainland.” Here, he says, the lifestyle of residents is more likely to be service-oriented rather than luxury-oriented. Sadly, he notes, moving west from the coast, a considerable proportion of the people in Pompano Beach find themselves struggling to make ends meet with extremely low income levels. Nonetheless, “Pompano Beach has some nice cultural centers, and everybody is trying to improve their communities. But because it’s out of the main Fort Lauderdale ritzy and expensive district, they don’t have money that flows like wine.”

Among these communities, notes Evans, the Avondale section of Pompano Beach is a very low-elevation and low-income community. As a result, it has suffered during high water. An Avondale stormwater project was designed to eliminate the hardship of flooding from rainfall, storms, and tides. “There used to be a storm drainage outlet there, but when the stormwater flows and the water level comes up, or the high tide comes up, this entire section of town doesn’t drain. In fact, it brings the water back into the community up to the catch basins. This project was put in to make sure they have positive flow away from the neighborhood and into the canal, regardless of what’s going on with the weather and the tide.”

Fighting the Tides

Describing the situation in the neighborhood, he says, “All of the streets have catch basins and underground concrete pipes that bring water to the canal through a subsurface canal entrance pipe.” The pipe, however, is “inundated with water all the time, and the only thing that makes water flow one direction or the other is whether there is more pressure on the top of the streets than the elevation of the water in the canal. Then it naturally drains to the canal, but a lot of the time that canal is being influenced by high tide or storm winds blowing water and backing it up into the area.” It’s a common problem in South Florida. “When you’re maybe five or ten feet above sea level, when you start to get a little resistance to gravity flow back into the ocean for one reason or the other, that water stops flowing, and it backs up into the street making it hard to get around.”

The solution for the Avondale neighborhood was a set of two Grundfos 20-horsepower, 7,000 GPM axial flow pumps. “We provided two stormwater pumps and their accessories and a control panel that would turn them on when the water is high enough to be removed,” he says. “As the water comes up, the level controls can turn on one or both pumps, either separately or alternating. If the water is really coming up fast, they can both turn on together and pump the water out of the collection system through the bulkhead and into the canal.”

He explains, “Axial flow pumps send the water straight down the pipe, as opposed to some other type of pump application, where water comes into the pump and creates some additional energy circularly and then shoves it out.” An axial flow pump, whether the motor is submerged or on the surface, “is basically a pipe with the propeller on the end of a long shaft. It turns like a boat propeller and shoves water straight down the pipe or straight up the pipe. They are low flow, low head, low pressure, but are designed to move lots of water,” he says. “This pump turns on when the water levels come up a little bit, and it keeps water moving out of the basin.”

Less Is More

A customized control panel sets the impellers in motion when needed. Manufactured locally to the engineers’ specifications, the pumps have controls that are housed in a stainless steel cabinet and equipped with settings matching the needs and preferences of local utilities and end-users. “Everything we do is custom-made because users know what they like.”

Evans elaborates: “In a mature marketplace where everything has got to be pumped, and where people have been operating pumps in what I would call a contemporary way for 40 years, they’ve developed specifications and their own preferences. Everybody’s got a generator plug in a different place, a light bulb in a different place, but that’s where they want it.”

The pumps themselves required zero customization. “This is a relatively non-complex station,” he says. In this scenario, “Less is more. In a lot of these cases, especially when something breaks down, typically it’s because of complex subsystems, or monitoring, or SCADA, or somebody hit a light pole.” He says Murphy’s Law dictates when those breakdowns are going to occur, and that’s typically, “on Christmas Eve, or late night, when people get paid triple time, when technicians want to be at home unwrapping gifts with their families; that’s when something goes poof and water has to be moved, and that’s when reliability really counts. That’s why people specify robust, high-quality equipment. Grundfos makes a great product and the installation on their product is really good.”

Tuning in a New Station

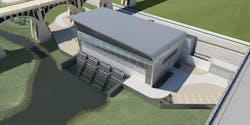

With a fast-growing drainage area undergoing rapid development, the City of Dallas needed to keep up the capacity of its downtown flood protection infrastructure. The 11.2 square miles of downtown behind the Trinity River levee had been under the watch of two existing Abel pump stations built decades ago. The existing pumps had been rebuilt and “were pretty old. A lot of this was original equipment from these old Abel pump stations,” says Chris Hill, construction manager for the City of Dallas.

A bit of history: during the 1920s and 1930s, floods destroyed thousands of homes in Dallas. In response, the city built 22 miles of levees, rerouted the Trinity River from its original location in the downtown area to a flatter area, and constructed a levee system to create a floodplain away from businesses and homes. “With the building of the levees, we had to come up with a way to move the water over and back into the river, and that’s when we started building these pump stations,” says Hill.

After historic floods in the 1960s, the levees were raised to 35 feet, and pumping capability was upgraded with the addition of a new pump capable of lifting water the increased elevation for discharge into the river. However, with recent development and a booming economy a generation later, officials in Dallas felt the time had come to improve the reliability of the flood protection system and increase public safety by modernizing the old pump stations.

Between the Levees

“The city of Dallas and this area are fairly flat,” and finding someplace for the water to go is a constant challenge, explains Lance Ferland, North Texas water business group manager for HDR, the consulting firm that oversaw the pump station project. Although the river is not usually very large, he says, “We can get some intense rainfall, and this river can grow I don’t know how many thousands of feet between the levees.”

The City of Dallas did a study in the 2000s and decided that providing the protection needed would require an especially robust pump. Hill says there’s a long list of key factors in the selection of a pump technology. Most importantly, he says, “It’s dependent on the amount of flow that you need to expel, and how high you have to pump it.”

The City began contemplating concrete volute pumps (CVPs). “Concrete volute pumps are made for very low head applications and are very good if you need up to 55 feet of head; if you have to go much beyond that you have to go to a different style of pump,” says Ferland. He notes that this type of pump is used often in European countries “where they have to deal with a lot of ocean water and lift water over low-lying areas. It’s very efficient very low maintenance,” he says. “You barely have to touch these pumps” once they are installed.

CVPs are vertical turbine-type pumps. “They are really large. Instead of the volute being made of steel, you actually mold the volute out of a high-abrasive type of concrete. The propeller fits on top of that and pumps the water that way,” he says. The whole pullout unit that Flowserve manufactures is 42 inches across; the propeller is 2.5 feet tall and 36 inches in diameter.

“What we have now are four pretty large pumps with four times the capacity of what the older Abel pumping stations could do. Those old pumps were decommissioned, and now just one half of the pump station gives the city more flood protection than what those two older pump stations that have been demolished were able to provide,” says Hill.

Pouring Over a Pump

Installation of the pump is very time-consuming, notes Hill. “The volute and the suction bell pieces are cast off site. They are pre-manufactured from Flowserve forms meeting their specifications. The forms were sent to the Dallas Metroplex area, and the bell and volute were cast on site by a company based in the Metroplex area.”

“The suction bell was started first,” says Ferland. “The suction bell and the volute are poured inside the foundation of the pump station—the first pour being the foundation, the second pour being the intake, and the third pour the suction bell. Flowserve sent a technician to make sure everything was centered correctly as the forms were filled with concrete. The pullout unit was brought in after we got the building up and could protect the unit from the weather before adding the propeller, the bearings, and the main drive of the pump itself.”

He continues, “From the city, we have a monthly maintenance schedule. These pumps are low-maintenance, but we monitor everything: lube oil temperatures, cooling water temperatures. Unlike a regular pump designed to start up as quickly as possible, these pumps have variable frequency motors powering a 3,500-horsepower drive, and they can start out very slowly so it doesn’t put a lot of wear and tear on the pumps. These pumps are supposed to last 50 years without needing to pull them for major overhaul.” He adds, “Flowserve has the data” to back up that claim from their experience overseas, and “that was one of the reasons we selected this pump.”

To keep the pumps going with their massive power requirement is a task in itself, but Dallas was up to the challenge. “Dallas is big on redundancy,” says Hill, “so we have three feeds to power the station. Each of those feeds can run half the pump station, leaving one feed as a backup in case they lose one of the primary feeds.”

Hill concedes, “It’s a heavy load; they don’t operate very often, just when we get the heavy rains, but when they do operate they are power hogs.”

Situation Under Control

The pumps are so powerful that even testing required special measures. “We couldn’t just turn these pumps on for a test, because the sump would drain in a matter of a minute, so we had to dam up the sump so we could recirculate it like in a bathtub,” says Hill. “We ended up having to have risers inside the sump that were tied to the discharge pipe of each of these pumps to carry out the test. We were shooting up 220,000 or 100,000 gallons a minute out of these test risers, and they were making these geysers 35 feet high under the bridge, so if you were driving on the bridge, you’d see a tremendous amount of water coming up. People were thinking there were some major pipe breaks going on out there.”

Once installed in the pump station, the pumps do their job with minimal human intervention. As Hill explains, Dallas’s pump stations are all unmanned and are operated by automated controls provided by SCADA software from HSQ. “It’s a system that we’ve been using for years; we’ve been using it to operate all our older stations.”

He says, “Sensors in the wells communicate with the system. When the water gets to a certain level, the first pump kicks in; if it continues to rise it goes into high speed; if the water continues to rise, another pump kicks in, and so forth. If we had an emergency and lost communication with the station, we have manual controls in the pump station so someone can go in there and turn the pumps on.”

The project is in the last phases and completion is scheduled for August. The first two new pumps came online before the old ones were decommissioned so the city would have flood protection as the project progressed. “Now, we’re connecting the piping over the levee for the other new pumps and getting really close to getting that all put together. We have half a pump station that provides more protection than the other two old ones combined.”

He notes, “Right now the pumps run periodically, about every 12 to 15 hours because we get a constant flow of water into our sumps, which will eventually be taken over by our two low-flow pumps that are mainly for small rain events.”

Recently, the pumps have been run for eight hours continuously with no issues. “Once complete, part of the maintenance plan is to bump these pumps once a month to make sure they operate and things are working well. If they’ve been sitting for a long time, and if a rain event is expected in a week, we’ll go in the day before the expected rain and bump the pump for a revolution or so just to make sure everything is still working and we’re ready to go,” says Hill.

“The City of Dallas is very happy with its selection,” he notes. “This is our third station we’ve built like this.”

With nine containment ponds that feed into the pump station, Hill believes downtown Dallas now has a good cushion against flooding. “Our flood elevation is 400 feet, and our pumps kick in at 379 feet. We would not see flooding until it’s at 400, but with this new pump station, we haven’t got to that level with the last two big rain events,” he says.

Hill reflects that in 2015, prior to the new station coming online, Dallas saw levels go up to 402 feet during a rain event because the older pump stations “could not keep up, and we did see some street flooding parking garage flooding.” Ferland notes that the new pump station is so robust that even during a 100-year event it would keep the elevation below 392 feet, well below flood elevation.

“We had two heavy rain events in October and November, and we only had to have one pump to handle what it would have taken five of the older pumps to handle. Had we gotten more rain, the other pump would have kicked in and we would have had that much more capacity. We’re very happy with the performance of the pumps at this time.”

He adds, “Here in Dallas we can get seven inches of rain in a couple of hours that can flood our down-town district and our parking garages. This is going to help significantly.”